available for pre-order

Torq

FOUNDATION

FOUNDATION

TORQ is now available for pre-order with limited quantities delivering between now and September. Deposits reserve your TORQ Bundle. First come first serve.

To select your specific bundle and quote, you should schedule a call with a NODO specialist.

Torque is the force that drives camera movement—pan, tilt, and roll. We named this series Foundation because it sets the new standard for unified torque control across any application.

TORQ isn’t just a product—it’s a modular ecosystem of motors, hardware, electronics, and software you can adapt for fluid heads, remote heads, handheld rigs, or custom designs. This is a new concept, built from years of prototypes and real-world tests, and lets you shape the system exactly as you imagine.

Foundation is just the start—these are the first components in a growing ecosystem you’ll help evolve.

Instead of a single-purpose product, we focused on every detail—from bolts and joints to software protocols and connectors—so parts are interchangeable for years.

Upgrade parts, not the whole system—motors, electronics, and accessories are all swappable for seamless evolution. Our software is built with backward compatibility, ensuring new features and protocols work with every unit, both now and in the future.

We’re launching more than hardware—we’re building a modular platform for every kind of camera motion, from dollies to stabilizers. This is just the first chapter. Join our early-adopter program and help shape the future of torque-controlled camera movement.

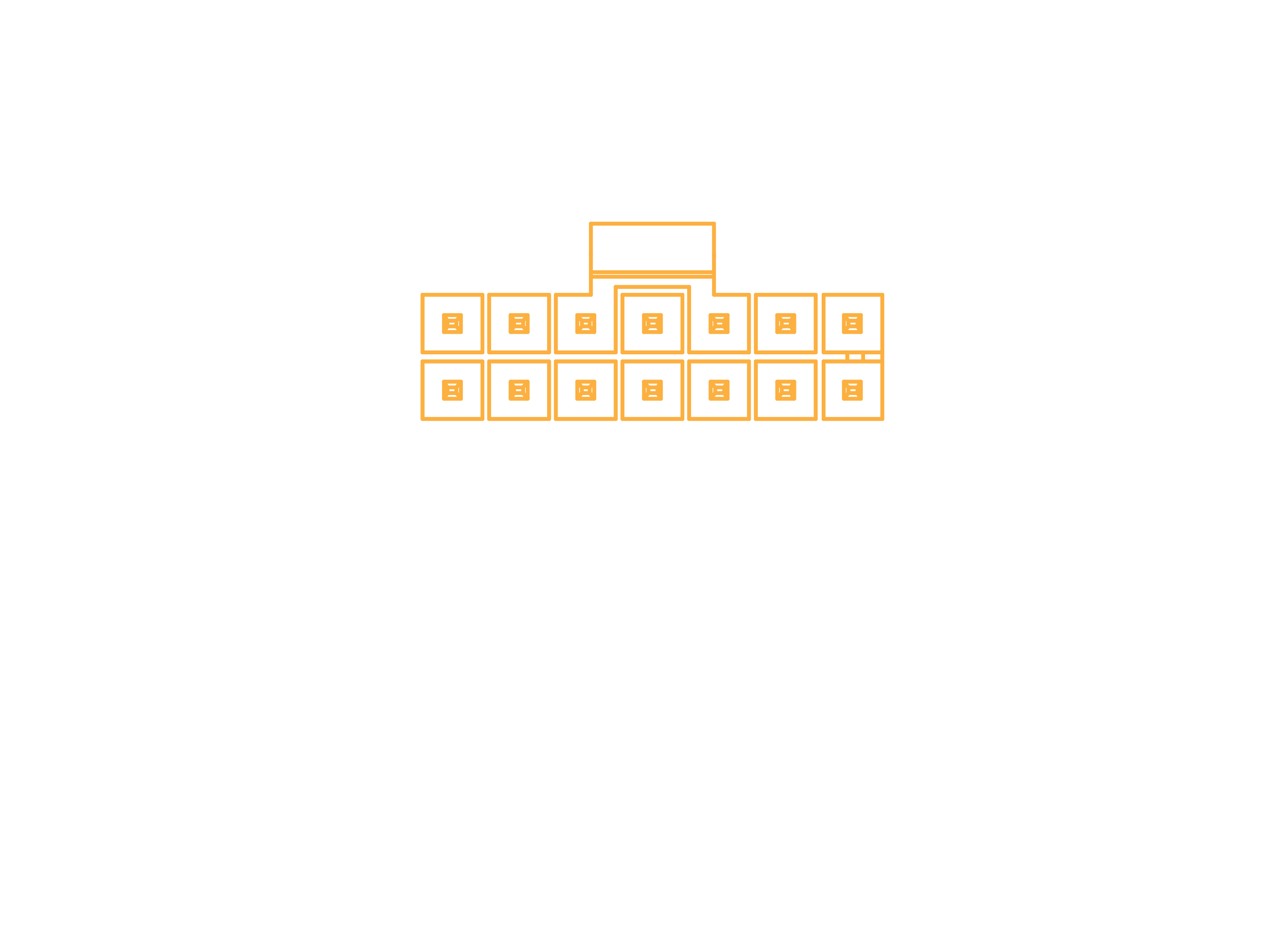

NODO has developed three unique, next-generation Inertia Motors which are the building blocks at the core of TORQ Builds. Each motor uses the most advanced modern PCB Stators and inherits NODO’s patented digital Mass and Drag.

Dense with torque.

Small but mighty.

A giant slewing ring aperture motor.

To meet the demands of modern cinematography, a TORQ Build can shrink, expand, shed motors, and more to meet your needs. These are some of the Builds available with different Build hardware and software.

Standard

Large Builds

Single Axis Steadicam or Handheld

Ultra Compact

2-Axis Tilt and Roll

To facilitate TORQ’s revolutionary modularity, NODO has included a suite of capabilities in each and every motor. This allows each motor to function independently or together in distinct Builds.

Stabilization in all Builds

iOS/macOS App Connectivity

10-48V Power/Data Network

Every 10-15°

No internal cabling for 360° moves

Assignable functions and presets

Firmware | Controllers | I/O

Standardized bolts

TORQ has inherited the Inertia Wheels’ SOC Award Winning digital mass and drag, so you can simply touch TORQ to pan, tilt and roll—exactly like a fluid head. And thanks to the modularity of the software, you can even do dual mode, where certain axes are remotely controlled, while others are directly controlled.

And, coming soon, a world first, stabilized fluid head mode, where you can operate directly, while the motors actively stabilize the payload.

Coming soon, TORQ will offer follow modes like other handheld gimbals.

Control TORQ with NODO’s Inertia Wheels or Ignite Digi’s Control Deck for joystick control. Both options have excellent wireless range up to and exceeding 1 mile. Or optionally hardwire Inertia Wheels for simple robust connection.

Mount TORQ to a crane—underslung, overslung, or even on its side. With advanced stabilization features, it works seamlessly with the latest self-leveling or non-leveling heads. Thanks to accessories like T-Rex Arms and the Diving Board, TORQ is ready to be the smallest crane-mounted remote head you’ll likely ever use.

TORQ is perfectly at home on a dolly. With both Fluid Mode and Remote Mode, it’s ready whether the operator is riding along or operating from a distance. Instantly adapt to the needs of the shot—or even the take—without downtime or reconfiguration.

TORQ offers several handheld options. Operate with just the Saturn ring motor for action scenes—Saturn keeps the horizon steady. Hang a 2-Axis VVS from an Easy Rig for tilt and horizon stabilization, or go full 3-Axis NVVS mounted to speedrail or a ring for complete handheld control.

Coming soon: TORQ is vehicle-mount ready. Its ultra-low weight means less counterweight, enabling faster arm car moves and requiring less power from your arm for faster accelerations.

TORQ’s ultra-light weight, low profile, and modularity make it an ideal choice for Steadicam. Build and rebuild in minutes, switching from 1, 2, or 3-axis configurations with virtually no need to rebalance. Get the flexibility to choose the perfect setup for each shot.

Instantly switch from fluid head to remote head with a button push. Move from handheld to remote in seconds by sliding Saturn into an NVVS build. TORQ is designed so you can build once and change modes on the fly—no downtime, just adaptability.

Created by a working DP, TORQ is designed for modern cinematographers balancing the nuances and tradeoffs of today’s sets. TORQ liberates the camera, reduces downtime, and lets you fit, move, and create anywhere—without switching platforms. It’s made to speed up your day and unlock creativity.

TORQ is engineered for Steadicam operators, built around dynamic balance and symmetry. It fits easily on a sled and just as easily comes off for other operating needs. It’s a universal tool for controlling camera inertia and torque—adaptable to every shot.

TORQ expands and contracts to suit Key Grips and Head Techs. Shrink it to fit the smallest spaces or expand for larger cameras. Mount in any orientation. Hardware is simple to modify, so you can machine your own accessories and mounts as needed.

TORQ is built as a home for a camera for run-of-show. At prep, a rental tech can balance the camera body on TORQ Build once, and it’s set for the duration. During the shoot, ACs can quickly rebalance lens changes just like with a classic fluid head—front to back. TORQ is durable, field-serviceable, and upgradable.

TORQ supports servo zooms with Ignite Digi Control Deck and Fusion Hub. Multi-cam broadcast panel and IP control are coming soon. Weighing just 18 lbs, it’s perfect for wire cams, cable cams, rail cams, and cranes. A dedicated pan-tilt build for simple multi-cam setups is on the way. Its modularity is ideal for vendors bidding on projects at any scale.

Investing in remote heads, gimbals, stabilizers and/or fluid head are a big decision for production companies. TORQ unifies your workflow and investment. It is the first to cover everything from remote head to fluid head to cable cam or crane. Its low weight, compact size, and flexible design make it a versatile asset for agile productions.

These specifications are subject to change. Due to the modular nature of TORQ Builds, specifics to individual Builds may vary.

| Component Weight | kg | lb |

|---|---|---|

| "Nexus" Pan Motor | 2.00 | 4.40 |

| "Vector" Tilt Motor (Single) | 1.16 | 2.55 |

| "Saturn" Roll Motor | 2.35 | 5.17 |

| Yoke (Pair) | 0.58 | 1.28 |

| TB-50 Plate (Single) | 0.26 | 0.57 |

| Quick Release Plate | 0.38 | 0.84 |

| Mitchell Mount | 0.95 | 2.09 |

| Two Axis Steadicam Plate | 0.12 | 0.26 |

| One Axis Steadicam Plate | 0.28 | 0.62 |

| Build Power | Value |

|---|---|

| Max Input Voltage | 50 Volts |

| Min Input Voltage | 10 Volts |

| Ideal Voltage | 15–32 Volts |

| Connector Type | AXIO |

| Max Current on AXIO | 18 Amps |

| Protection | Reverse Polarity, Over Current, Undervoltage |

| Data Type | RS-485 |

| Assembly Weight | kg | lb |

|---|---|---|

| 3 Axis - NVVS | 8.00 | 17.60 |

| NVVS w/ TB-50 Plates + QRP + Mitchell | 9.85 | 21.67 |

| 2 Axis - VVS | 6.12 | 13.46 |

| 1 Axis - S Solo | 2.63 | 5.79 |

| Max Payload by Application | Max Payload Lb | G-Forces |

|---|---|---|

| Jib | 60 | 1.25 |

| Techno / Readyrig | 50 | 1.5 |

| Pursuit Vehicle w/ Isolator | 30 | 3 |

| AUXIO | Value |

|---|---|

| Connector Type | Molex 14-Pin Nano |

| Regulated Output | 5 Volts @ 1 Amp |

| Unregulated Output | AXIO Voltage @ 2 Amps |

| Data Protocols | UART TTL, RS-485 Full/Half |

| Stabilization | Value |

|---|---|

| IMU Type | Gyro, Accelerometer, Compass Fusion |

| IMU Location | In every motor |

| Drift | 2–9° / Hour |

| Available Algorithms | 1-Axis, 2-Axis, 3-Axis |

A "Build" is a specific configuration of TORQ ecosystem components—assembled from modular motors, mounts, control hardware, and software options based on your workflow. Whether you're building a single-axis tool for Steadicam or a fully stabilized three-axis system for cranes, each TORQ build is tailored to your needs.

TORQ is designed to evolve. You can reconfigure, upgrade, or expand your build over time, adapting your system as your tools, crew, or creative demands change.

Nexus, Vector, and Saturn are names for the core motor types within the TORQ ecosystem. Nexus is a high-torque motor often used for pan. Vector motors are compact and versatile, ideal for tilt or lighter axes. Saturn is a large-diameter motor purpose-built for roll and high-inertia payloads.

These identities reflect TORQ’s modular philosophy—motors are not locked into roles. You can configure them however your build demands, and because TORQ operates in any orientation, each motor type can serve different purposes depending on the application.

NVVS stands for Nexus–Vector–Vector–Saturn, the four-motor 3-axis TORQ. It combines high-torque and compact motors in a balanced layout optimized for performance.

NVVS is one of several possible motor combinations in the TORQ ecosystem. This designation is used across software, manuals, and purchasing to clearly reference this specific build format.

VVS stands for Vector–Vector–Saturn, the three-motor 2-axis TORQ build commonly used for Steadicam, handheld, or vehicle-mounted configurations where pan is handled manually or externally.

VVS is one of several modular combinations in the TORQ ecosystem. This designation is used across software, manuals, and purchasing to clearly identify this specific build format.

Saturn Solo refers to a 1-axis TORQ build that uses only the Saturn motor for stabilized roll control—ideal for Steadicam or handheld operators looking to isolate and refine horizon stability.

As with other TORQ builds, "Saturn Solo" is a technical designator used across software, manuals, and purchasing to identify this specific single-axis configuration.

There are several mount options. The motor itself has an M4 boss pattern for ultra-compact builds.

On top of that, there is a wide-body, low-profile Quick Release Plate (QRP) with a v-taper wedge design that interfaces with a Quick Release Base (QRB). The QRB offers many mounting options: M6, 3/8"-16 cheese plate (1/2" spaced), and even Mitchell threads.

Interfacing with the QRB, a full dual-standard Mitchell mount is available. We call it “dual-standard” because it supports both the original Ronford-Baker standard and a secondary flat bolt-and-hole Mitchell standard. TORQ’s Mitchell mount is dual-standard because it has removable components to securely mate with both.

A single-axis mounting plate with multiple 1/4-20 and 3/8-16 threads is included with most bundles that can attach at any 90° position around the Saturn motor. It includes vertical stabilizer arms to help keep the Saturn motor rigid and square to the mount. It can be used on Steadicams, handheld, or mounted in another gimbal to unlock 360° roll.

Switching TORQ build types depends on the configurations involved. For example, moving from a 3-axis NVVS to a 1-axis Saturn Solo can be as simple as using a button preset to change modes. Other transitions may involve reassembling onto a different set of hardware modules.

TORQ is designed to streamline this process. All build hardware uses T20 Torx M4 bolts, and accessories use captive, self-aligning fasteners—keeping every change fast, clean, and repeatable.

Yes!

TORQ uses the same type of patented Inertia Motors found in the Inertia Wheels, and thus has inherited the same touchable, human interface as the Inertia Wheels, allowing operators to directly touch and interact with the motors. We call this mode “Fluid Head Mode” because it emulates the drag and friction of a fluid head, but this effect is created digitally.

Going one step further, TORQ can actually create digital mass, just like the Inertia Wheels. So a small, lightweight camera can instantly feel heavier and move with the smooth inertia of a larger camera. You have to feel it to believe it.

Yes, all motors can move 360° infinitely. There are no internal cables. You do need to watch for external cables, particularly if you power the camera off the head or tilt infinitely.

Yes. In the NVVS Build when the Vector motors are at 90°, this is called “singularity,” and TORQ NVVS has software that allows it to look through this position and stabilize with available motors.

Yes. Foundation Nexus motors have a strong axis capable of holding the payload at extended angles. The stabilization software does not care what angle the system is at; it can operate at any angle and can even handle changes in angle during a shot.

Yes, in a few different Builds and form factors. Currently, it supports single-axis handheld operation with the Saturn motor in Solo mode. It will support follow modes in the future; that is coming soon.

Yes. With the Ignite Digi Control Deck, DJI Transmission, and Fusion Hub, you can control various lens motors, including broadcast Fujinon and Canon servos.

This will be available via Ethernet as purchasable software for those who need it.

TORQ features very precise encoders, powerful motors, and a high-speed data network—essential ingredients for motion control and repeatability. However, achieving true repeatability with a stabilized platform is challenging.

Motion control capabilities are currently in the software roadmap. Out of the box, the Inertia Wheels support record and playback, but it’s important to note that as a stabilized gimbal, factors like gyros, balance, tuning, and future software updates all impact “frame-accurate” repeatability. For this reason, we cannot guarantee precise motion control repeatability at this time.

TORQ has been used for car work, especially car interiors due to its small size. However, for more aggressive vehicle applications, we recommend waiting until upcoming software updates are released. We are currently focused on increasing stabilization bandwidth and are targeting solid firmware for car-to-car work by August.

That would require a very large drone. If you are interested in mounting TORQ on a drone, please contact us to discuss your project.

Not currently. We are working on simplifying and streamlining the tuning process, but early adopters should be familiar and comfortable with manual motor tuning.

The exact torque specification is not public, but our torque density is exceptionally high given the structural design of TORQ, where most components by weight are torque-generating.

We are still finalizing the dust and water rating for TORQ. As of now, the electronics are sealed with a conformal coating, but no official testing has been conducted in extreme environments yet.

The Inertia Wheels, which use similar motor drivers, have been successfully used around the world in harsh and remote conditions. TORQ builds on this with even higher-performance components, advanced encoders, labyrinth seals, and additional protective treatments. While we are confident in its potential for extreme environment performance, no official performance guarantees can be made until further testing is complete.

TORQ is designed to be voltage and battery agnostic. It can operate between 10–48V DC, with 10–32V being ideal. There are no torque gains at higher voltages.

Users should avoid regulated power sources (such as block batteries that step 14.4V up to 28V) and use direct, unregulated batteries whenever possible.

Maximum torque/current is adjustable to allow a range of power supplies to be used. Ignite Digi makes TB50 and TB51 battery plates that can be mounted in various places, including back-mounted or onboard TORQ.

The max payload specification is roughly 60lbs, but this is a poor rule of thumb that we wish the industry would not use. In reality, the actual payload limitations are defined by the payload size, the g-forces it will experience, and the type of camera operation.

12.5kg at 3g, 22.5kg at 2g is essentially the maximum mechanical stress. If you would like the actual payload chart, please email logan@nodo.film.

The roll diameter is 180mm; however, the camera body does not go through the roll aperture—only the lens mount or lens does. Unlike other gimbals that balance by sliding the entire payload through the roll, TORQ NVVS balances by sliding the whole roll assembly (camera, lens, and Saturn motor included) forward and backward via the side dovetails between the Saturn and Vector motors. This is a unique assembly, and one of its main benefits is that the actual payload diameter is 290mm.

Yes, AXIO allows power to pass through from the battery. Whatever voltage you put into the head will be output on the other side. Ignite Digi is making a voltage regulator that will allow lower-voltage cameras to be powered from higher-voltage batteries.

Yes, the AUXIO connectors have 5V regulated and unregulated out.

That’s a difficult question to answer, as battery life depends greatly on your payload and how the system is used. Compared to other gimbals of similar size and weight, assuming similar torque and duty cycles, you can expect TORQ to run substantially longer due to its large-diameter PCB stator motors.

TORQ motors are very quiet, though some audible noise may be heard during strong accelerations. This noise is generally not noticeable in sync sound situations. Users can further adjust motor sound characteristics through tuning settings, and so far no testers have reported sound issues.

Any camera you can mount on 15mm LWS rods can mount on TORQ.

Some cameras such as Alexa 35, can slide right onto Ignite Digi’s BUD plates. And others such as Venice, Rialto, RED V-Raptor, RED Komodo(-X), Alexa Mini (LF) have other dovetails or plates that allow rigid, perfectly nodal mounting. For smaller cameras, like FX3, we offer lens supports for C7 adapters for both nodal and rigid mounting at the lens mount. This ensures optimal stability and quality of motion.

Anything you can mount on 15mm LWS, 15mm rods, 19mm rods, or bolt onto a cheese plate can be mounted on TORQ. In total it has 290mm diameter aperture that accessories near the Saturn motor can fit inside. Once you are a few inches from the Saturn ring—like near the matte box or battery plate of the camera, the diameter opens up even more.

Balancing TORQ follows a simple but specialized process. For lens changes, only front-to-back balance is typically needed—just like a fluid head.

For full builds, we recommend dynamic balancing. Start by balancing the camera body and rear accessories on the Saturn motor (roll axis). Then adjust front accessories using the rod-mounted placement points designed for quick fine-tuning.

Once those are set, your system will stay balanced throughout most of the shoot. After mounting your lens, finalize the setup by balancing front-to-back on the Saturn’s tilt dovetails. Because the tilt and pan axes are always aligned, balancing one also balances the other.

This process keeps the TORQ build both statically and dynamically balanced—reducing centrifugal effects and increasing performance.

NODO makes the best wheels—the Inertia Wheels MAX, which recently won the SOC Technical Achievement Award for their outstanding performance, and the more affordable Inertia Wheels Brushless. Simply mount the Inertia Wheels’ receiver to any motor on TORQ.

The Ignite Digi Control Deck will soon work with TORQ utilizing DJI Transmission for long-range joystick control. NODO is also working on IP control over ethernet for broadcast multi-cam setups. This is coming soon.

Yes, with the Inertia Wheels. We sell 100 ft. hardwire cables and have made cables up to 1,000 ft. on request.

Yes. Image Relative control means that, however the camera is rotated, panning is always in the camera’s panning axis and tilting is always in the tilting axis. The latest version of TORQ NVVS software can operate with Image Relative control or with Global control. Global control means panning is always in the horizontal axis relative to gravity, and tilting is always in the vertical axis relative to gravity.

All TORQ motors have Bluetooth. To use other wireless controllers, you will need to connect the controller’s receiver, such as the Inertia Wheels’ Receiver.

Each motor includes a Bluetooth transmitter and can be connected to using our NODO TORQ app on iOS or macOS. The app enables you to quickly adjust both basic and advanced settings, view real-time charts with high-resolution data, and save or share settings profiles. Settings can be exported as .ndtq files and easily shared via email, iMessage, AirDrop, or even WhatsApp.

That depends on your needs, as a TORQ Build can be 1, 2, or 3 Axis. Functional Build Bundles starts around $20,000 and can go as high as $60,000 if you want all the options.

You can upgrade at any time. All Build hardware, build software, accessories, and mounts are a la carte with market prices. Upgrading is easy and can be done at any time. With each piece of build hardware and software you buy, your TORQ gains functionality and grows in what challenges it can tackle.

Separating software from hardware is a core part of TORQ’s modular, scalable, and sustainable product design. It avoids hardware obsolescence, keeps support stable, and allows users to pay only for what they need. This approach lets NODO serve a wider range of users and use cases with the same hardware, ultimately making the entire product line more robust and future-proof.

When you purchase software for your TORQ—such as the Pan→Tilt→Roll Stabilization Algorithm—you own that feature permanently. Your purchased software will be supported, receive firmware updates, and be developed to maturity at no additional cost.

Yes. TORQ ships in an SKB 3I-2217-8 case with custom foam.

TORQ comes with a global 1-year warranty as specified in our Terms and Conditions. For regions with different standard warranty requirements, NODO complies with all local regulations where a reseller is present.

All accessories are offered a la carte, allowing you to customize your order to fit your needs. However, we also offer suggested bundles that include essential accessories as a starting point. Our team is available to help you determine which accessories you may want to purchase initially or save for a future upgrade.

Yes! TORQ is fully modular and field-serviceable. Most parts are available a la carte, and some may require remote activation for purchased software support.

Our 30-day return policy is outlined in the Terms and Conditions. We work hard to ensure customer satisfaction and are proud of our extremely low return rate.

We are committed to reducing hardware obsolescence in the film industry. TORQ’s modular design and a la carte business model make upgrades easy and affordable. As new technology is released, we strive to offer existing users the best possible upgrade paths.

For example, we have offered discounted upgrades to Inertia Wheels MAX for previous customers and continue to provide upgrade paths. TORQ is designed for field servicing and straightforward component-by-component upgrades, ensuring that costs remain lower than traditional hardware replacement models.

General firmware and software updates improving and adding many new features are free. Some software and stabilization algorithms are individually sold. All a la carte software comes with its own included free software support, service, and may include training.

Once you use TORQ, you’ll understand why. We’ve taken the time to lay the right Foundation. Good things come to those who wait.

TORQ software is currently in Beta and will continue to receive rolling feature updates during this period. The software already supports both 3-axis and 1-axis operation modes.

The development team is actively working on higher-frequency stabilization (such as for car-to-car work), advanced singularity handling (for looking straight down), and stabilized fluid head mode.

Future updates will expand support for 2-axis Steadicam stabilization, as well as new features for broadcast workflows and VFX applications.

We have an internal roadmap which will dramatically expand TORQ's capabilities and use cases with new hardware and software. Our long-term vision includes modular electronic upgrades that will increase future performance while using the same core hardware.

We are also exploring ways to support applications outside the traditional film and broadcast industries. In addition, we are collaborating with third parties to help standardize new workflows and ecosystems for the future.

There is no single printable manual at this time. However, active users have access to a live online site with up-to-date guidance, firmware, and feature information, which we update regularly as the product evolves.

Yes, we recommend customers pick up their TORQ in person to take advantage of a one-on-one training session covering all the basics.

Every TORQ comes with direct contacts at NODO for fast and responsive support. We are releasing TORQ at a responsible pace to ensure we can provide excellent support to all active customers.

Reserve yours.

Get a customized quote.